Application of laser quenching in metal strengthening treatment

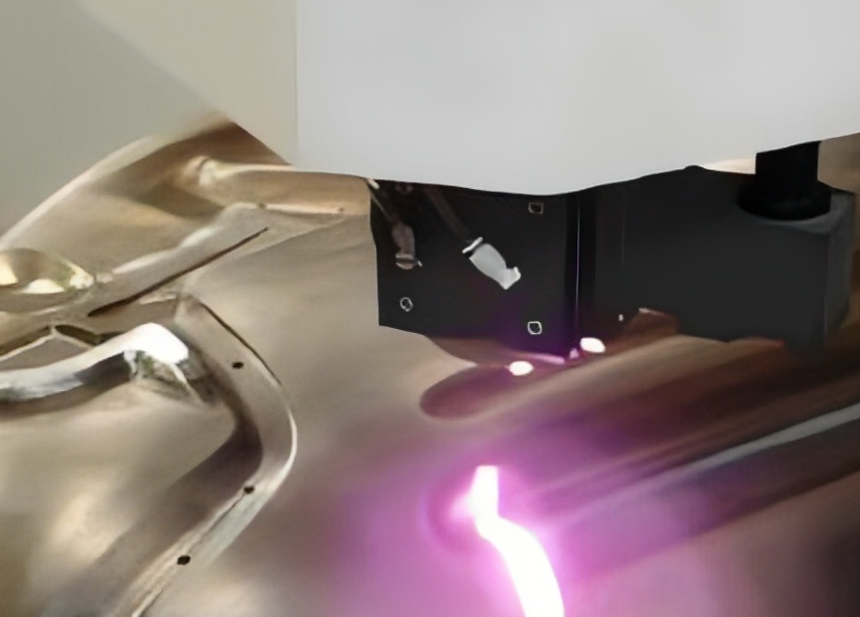

laser-quenching

Laser quenching uses high-energy laser as the heat source to rapidly heat and cool the metal surface, instantly performing the quenching process to obtain a high hardness and extremely fine martensitic structure, improving the hardness and wear resistance of the metal surface, and generating compressive stress on the surface to enhance fatigue strength.

Laser quenching characteristics

1. Selective quenching

The laser spot is adjustable, allowing quenching to be carried out on parts of arbitrary total width; Secondly, the laser head coupled with multi axis robots can perform quenching on specific areas of complex parts.

2. High efficiency

Laser quenching is extremely hot and rapidly cooled, and the quenching process is carried out in a very short time.

3. High hardness

Taking 45 # steel as an example, its hardness can reach above HRC60. It is also possible to control the hardness of quenching according to the actual processing requirements.

4 small grains

The martensite grains obtained by laser quenching are extremely fine, the texture density is higher, and the surface wear resistance is greatly improved.

5 small deformations

Laser quenching is extremely hot and rapidly cooled, with a small heat hazard zone and low quenching stress and deformation. The deformation of the workpiece before and after laser quenching can be basically ignored, making it particularly suitable for surface treatment of high-precision parts. 6 Intelligent Environmental Protection

Laser quenching does not involve substances such as oil or water, and will not cause environmental pollution.

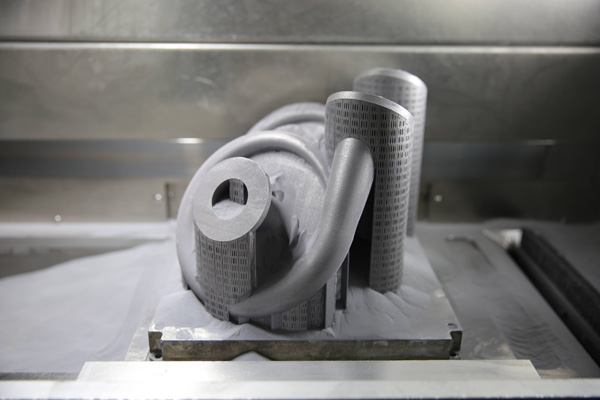

Application of laser quenching

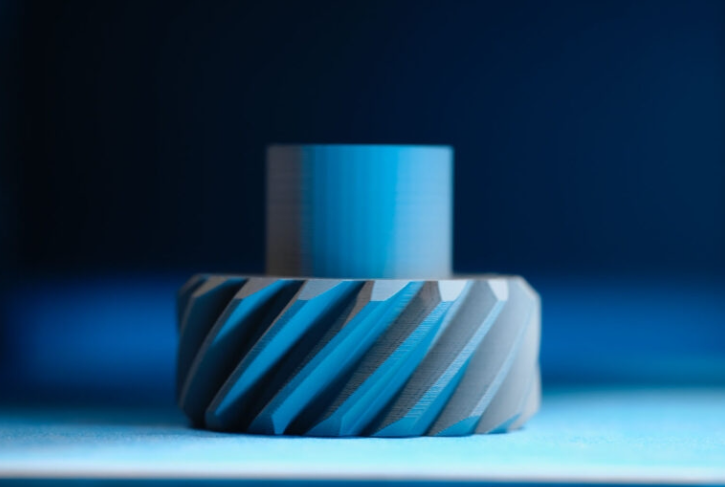

Laser quenching has been successfully applied to the surface strengthening of spare parts in the automotive industry, mold industry, hardware tools, and machinery industry, especially in improving the service life of gear, shaft surface, slide rail, shaft, mold shell and other spare parts. The effect is significant and has achieved significant economic and socio-economic benefits. In recent years, surface reinforcement of components such as threaded joints and small and medium-sized shaft necks has become increasingly common.

Laser quenching can be applied to a wide range of materials, including medium to high carbon steels such as carbon steel, alloy steel, bearing steel, and pig iron. Generally for those who do not require overall quenching, have high specifications and precision requirements, and strict deformation control; Strengthening the surface treatment layer of workpieces that cannot be processed by other methods or have complex appearances and require further improvement in hardness, wear resistance, and other properties has obvious advantages.

Add WeChat

Add WeChat