The metal powder used for 3D printing was originally produced in this way

Nowadays, when it comes to 3D printing, I believe everyone is familiar with it. Our column has previously introduced many applications of 3D printing, such as printing houses, bridges, etc. Today, we will talk about an important material used in 3D printing - metal powder.

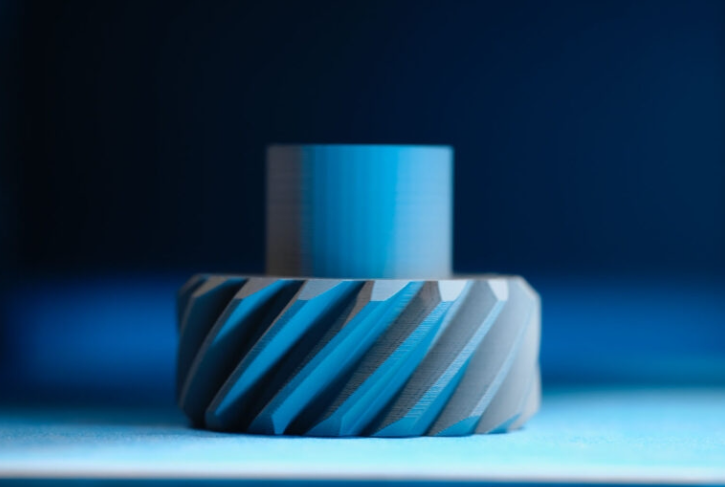

(1) Titanium alloy, aluminum alloy, stainless steel, and many other metal powder materials that can be used for 3D printing are widely used printing consumables in 3D printing. They mainly include four types in form: liquid photosensitive resin materials, thin materials, low melting point wire materials, and powder materials; In terms of composition, it covers almost all types of materials in current production and life, including polymer materials such as plastics, resins, and waxes, metal and alloy materials, ceramic materials, etc. Among them, the most cutting-edge and promising is undoubtedly metal powder 3D printing. According to consulting firm SmarTech's prediction, the global market size for metal powder additive manufacturing will reach 11 billion US dollars by 2024.

At present, the types of metal powder materials for 3D printing include stainless steel, mold steel, nickel alloys, titanium alloys, cobalt chromium alloys, aluminum alloys, and bronze alloys.

Iron based alloys are the most important and widely used metal materials in engineering technology, often used for forming complex structures, such as stainless steel for 3D printing. Compared with traditional casting and forging techniques, they have high strength, excellent high-temperature resistance, wear resistance, corrosion resistance and other physical, chemical and mechanical properties, as well as high dimensional accuracy and material utilization. They are widely used in industries such as aerospace, automotive, shipbuilding, and machinery manufacturing.

Titanium alloys have excellent strength and toughness, combined with corrosion resistance, low density, and biocompatibility, making them ideal for many high-performance engineering applications in aerospace and automotive competitions. They are also used in the production of biomedical implants, with high strength, low modulus, and strong fatigue resistance.

Cobalt chromium alloy is commonly used in surgical implants such as alloy artificial joints, knee joints, and hip joints due to its high wear resistance, good biocompatibility, and nickel free (nickel content<0.1%) characteristics. It can also be used in engine components, wind turbines, and many other industrial components.

Aluminum alloy is the most widely used type of non-ferrous metal structural material in industry, with low density, high specific strength, close to or exceeding high-quality steel, and good plasticity. Research has shown that aluminum alloys used in 3D printing can achieve parts that are dense and have a fine structure, with mechanical properties comparable to or even better than castings. Compared to traditional process parts, their quality can be reduced by 22%, but their cost can be reduced by 30%.

Copper alloys have excellent thermal and electrical conductivity, and copper with excellent thermal conductivity in thermal management applications can combine design freedom to create complex internal structures and conformal cooling channels.

(2) How are metal powders used in 3D printing produced?

The preparation methods of metal powder can be mainly divided into reduction method, electrolysis method, grinding method, atomization method, etc. according to the preparation process. The two most advanced powder production processes commonly used in China are argon atomization method and plasma rotating electrode method.

1. Argon atomization method

The argon atomization method for powder production is a method of powder production that utilizes a rapidly flowing argon gas stream to impact a metal liquid, breaking it into small particles and then condensing them into solid powder.

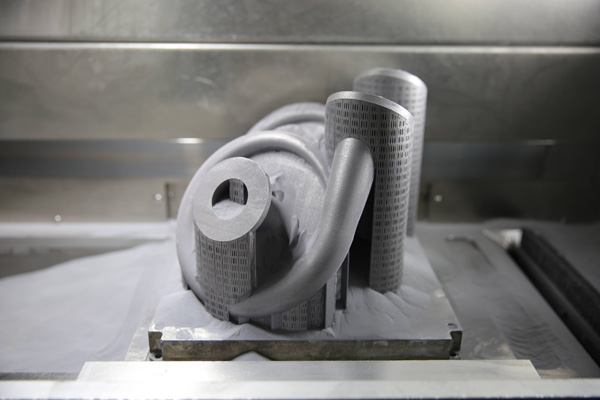

2. Plasma rotating electrode method

The plasma state is known as the fourth state of matter, and the process of plasma rotating electrode atomization (PREP method) powder production can be simply described as follows: metal or alloy is made into a consumable electrode, and the end of the consumable electrode is melted to form a liquid film under the action of a coaxial plasma arc heating source. The liquid film is ejected at high speed under the action of rotational centrifugal force to form droplets. The molten droplets rub against the inert gas (argon or helium) in the atomization chamber and are further broken under shear stress. Then, the droplets are rapidly cooled and solidified into spherical powder under the action of surface tension.

The metal powder produced by plasma rotating electrode method has the following advantages:

High sphericity, smooth surface, good flowability, and high loose density, resulting in good powder spreading uniformity and high density of printed products; The powder has small particle size, narrow particle size distribution, low oxygen content, less/no spheroidization and agglomeration during printing, good melting effect, high surface smoothness of the product, and the consistency and uniformity of printing can be fully guaranteed; There are basically no hollow powders or satellite powders, and there are no defects such as air gaps, entrapment and precipitation pores, cracks, etc. caused by hollow spheres during the printing process.

(3) What are the performance requirements for metal powders in 3D printing?

We just mentioned many metal powders that can be used for 3D printing. So, what conditions do metal powders need to meet to meet the material requirements of 3D printing?

1. Purity level

Ceramic inclusions can significantly reduce the performance of the final product, and these inclusions generally have a high melting point, making it difficult to sinter and form. Therefore, there must be no ceramic inclusions in the powder.

In addition, the oxygen and nitrogen content also need to be strictly controlled. At present, the powder preparation technology used for metal 3D printing is mainly based on atomization method. The powder has a large specific surface area and is easy to oxidize. In special application fields such as aerospace, customers have stricter requirements for this index. For example, the oxygen content of high-temperature alloy powder is 0.006% -0.018%, titanium alloy powder is 0.007% -0.013%, and stainless steel powder is 0.010% -0.025%.

2. Powder particle size distribution

Different 3D printing equipment and forming processes have different requirements for powder particle size distribution. At present, the commonly used powder particle size range for metal 3D printing is 15-53 μ m (fine powder), 53-105 μ m (coarse powder), and in some cases, it can be relaxed to 105-150 μ m (coarse powder).

The selection of metal powder particle size for 3D printing is mainly based on different energy sources of metal printers. Printers using laser as the energy source are suitable for using 15-53 μ m powder as consumables due to their fine focused spot and easy melting of fine powder. The powder supply method is layer by layer powder spreading; A powder spreading printer using an electron beam as an energy source has a slightly coarse focused spot, which is more suitable for melting coarse powder and mainly suitable for using coarse powder with a diameter of 53-105 μ m; For coaxial powder feeding printers, powder with a particle size of 105-150 μ m can be used as consumables.

3. Powder morphology

The morphology of the powder is closely related to the preparation method of the powder. When a metal gas or molten liquid is transformed into powder, the shape of the powder particles tends to be spherical. When it changes from a solid state to a powder, the powder particles are mostly irregular in shape, while powders prepared by aqueous solution electrolysis are mostly dendritic.

Generally speaking, the higher the sphericity, the better the flowability of powder particles. 3D printing of metal powder requires a sphericity of over 98%, making it easier to lay and feed powder during printing.

The table above shows the metal powder morphologies corresponding to different powder preparation methods. It can be seen that, except for the gas atomization method and the rotating electrode method, the powder morphologies prepared by other methods are non spherical. Therefore, the gas atomization method and the rotating electrode method are the main preparation methods for high-quality 3D printed metal powders.

4. Powder flowability and bulk density

The flowability of powder directly affects the uniformity of powder spreading and the stability of powder feeding during the printing process.

Liquidity is related to powder morphology, particle size distribution, and bulk density. The larger the powder particles, the more regular the particle shape, and the smaller the proportion of extremely fine powder in the particle size composition, the better the fluidity; When the particle density remains constant and the relative density increases, the flowability of the powder increases. In addition, the adsorption of water, gas, etc. on the surface of particles can reduce the flowability of the powder.

Loose density refers to the mass of powder per unit volume when a powder sample is naturally filled into a specified container. Generally, the coarser the powder particle size, the higher the loose density, and powders with a combination of coarse and fine can achieve higher loose density. The effect of loose density on the density of metal printed final products is still uncertain, but an increase in loose density can improve the flowability of the powder.

conclusion

In recent years, China has actively explored the technology of 3D printing metal powder preparation, and currently has multiple sets of advanced powder preparation equipment put into application. However, overall, there is still a gap in powder preparation technology between China and foreign countries. Currently, high-end alloy powders and manufacturing equipment mainly rely on imports. In promoting the development of domestic 3D printing metal powder preparation technology, China still has a long way to go.

Add WeChat

Add WeChat