Application of laser cleaning

Laser cleaning technology is a rapidly developing new type of cleaning technology in the past decade, which has gradually replaced traditional cleaning processes in many fields with its own advantages and irreplaceability. Laser cleaning can be used not only to clean organic pollutants, but also to clean inorganic substances, including metal rust, metal particles, dust, etc. Below are some practical applications that have become very mature and widely used.

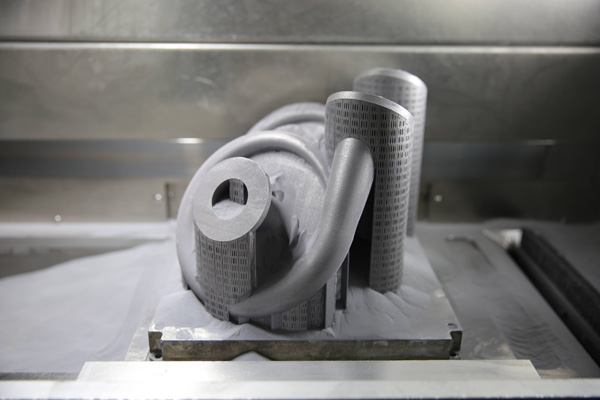

1. Cleaning of molds

Every year, tire manufacturers around the world manufacture hundreds of millions of tires, and the cleaning of tire molds during the production process must be fast and reliable to save downtime. Traditional cleaning methods include sandblasting, ultrasonic or carbon dioxide cleaning, but these methods usually require the high-temperature mold to be cooled for several hours before being transferred to cleaning equipment for cleaning. Cleaning takes a long time and can easily damage the accuracy of the mold. Chemical solvents and noise can also cause safety and environmental issues.

Using laser cleaning method, as laser can be transmitted through optical fibers, it has great elasticity in use; Due to the use of fiber optic connections for laser cleaning, the light can be directed to the dead corners or difficult to clean areas of the mold, making it convenient to use; Due to the non gasification of rubber, it does not produce toxic gases that affect the safety of the working environment.

The technology of laser cleaning tire molds has been widely adopted in the tire industry in Europe and America. Although the initial investment cost is high, the benefits obtained from saving standby time, avoiding mold damage, ensuring work safety, and saving raw materials can be quickly recovered.

According to the cleaning test conducted by Quantel's LASERLASTE laser cleaning system on the Shanghai production line, it only takes 2 hours to clean a set of large heavy-duty tire molds online. Compared with conventional cleaning methods, the economic benefits are obvious.

2. Cleaning of weapons and equipment

Laser cleaning technology is widely used in weapon maintenance and upkeep. By using a laser cleaning system, rust and pollutants can be efficiently and quickly removed, and the cleaning area can be selected to achieve automation. By using laser cleaning, not only is the cleanliness higher than chemical cleaning processes, but it also causes almost no damage to the surface of objects.

By setting different parameters, a dense oxide protective film or molten metal layer can be formed on the surface of metal objects to improve surface strength and corrosion resistance. The waste cleared by laser does not cause much pollution to the environment and can be operated remotely, effectively reducing the health damage to operators

3. Cleaning of old airplane paint

Laser cleaning systems have long been applied in the aviation industry in Europe. The surface of the aircraft needs to be repainted after a certain period of time, but the original old paint needs to be completely removed before repainting. The traditional mechanical paint removal method is prone to damage the metal surface of the aircraft, posing a hidden danger to safe flight. If multiple laser cleaning systems are used, the paint layer on the surface of an A320 Airbus can be completely removed within two days without damaging the metal surface.

4. Cleaning of building exterior walls

With the rapid development of China's economy, more and more skyscrapers are being built, and the problem of cleaning the exterior walls of buildings is becoming increasingly prominent. Laser cleaning systems provide a good solution for cleaning the exterior walls of buildings through optical fibers. They can effectively clean various pollutants on various stones, metals, and glass, and are many times more efficient than conventional cleaning. It can also remove black spots and color spots on various stones of buildings.

5. Cleaning in the electronics industry: Laser removal of oxides is used in the electronics industry, which requires high-precision cleaning and is particularly suitable for using laser to remove oxides. Before soldering the circuit board, the pins of the components must be thoroughly de oxidized to ensure optimal electrical contact, and the pins must not be damaged during the cleaning process. Laser cleaning can meet the requirements of use and is highly efficient, with only one laser irradiation required for each pin.

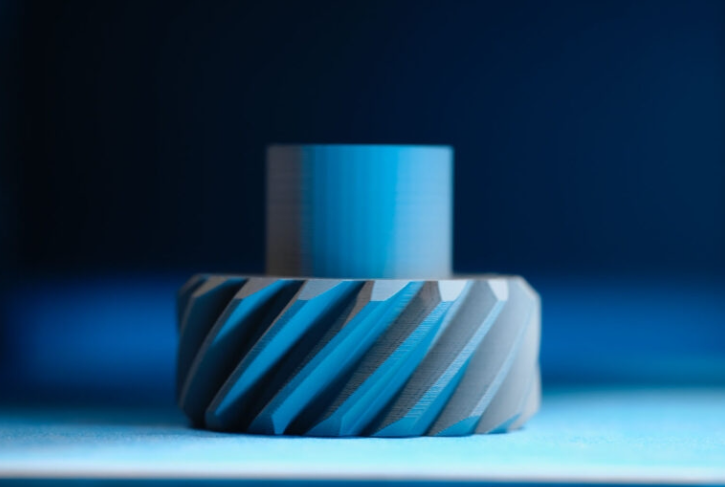

6. Precise degreasing and cleaning in the precision instrument industry

The precision machinery industry often requires the removal of esters and mineral oils used for lubrication and corrosion resistance on parts, usually through chemical methods, and chemical cleaning often still leaves residues. Laser degreasing can completely remove esters and mineral oils without damaging the surface of the parts. The removal of pollutants is accomplished by shock waves, where a thin layer of oxide on the surface of the parts explosively vaporizes to form shock waves, resulting in the removal of pollutants rather than mechanical interactions. Thoroughly degreasing of materials is used for cleaning mechanical parts in the aerospace industry. The removal of oil esters in mechanical parts processing can also be achieved through laser cleaning.

7. Cleaning of pipelines inside nuclear power plant reactors

Laser cleaning systems are also used for cleaning pipelines inside nuclear power plant reactors. It uses optical fibers to introduce high-power laser beams into the interior of the reactor, directly removing radioactive dust and making the cleaned material easy to clean. Moreover, as it is a remote operation, it can ensure the safety of the staff.

In summary, laser cleaning plays an important role in many fields, including automobile manufacturing, semiconductor wafer cleaning, precision parts processing and manufacturing, military equipment cleaning, building exterior wall cleaning, cultural relic protection, circuit board cleaning, precision parts processing and manufacturing, LCD display cleaning, and gum residue removal.

The application of laser cleaning in national defense and military equipment, such as paint removal and rust removal of various aircraft, rust removal of various ship equipment, rust removal of various weapon equipment, rust removal of various tanks and artillery, rust removal of various parts, etc., has broad prospects and huge potential for development trends. Especially the advantages of environmental friendliness, convenience, safety, and low-cost use of laser cleaning are obvious, making it a new, efficient, and safe process technology.

Add WeChat

Add WeChat