Process flow of metal 3D printing services

With the decrease in price, improvement in performance, and increase in market acceptance of metal 3D printing, metal 3D printing is being accepted by more and more customers. Metal materials for 3D printing are printed using SLM technology, which is selective laser melting forming technology. Below is an introduction to the process flow of metal 3D printing services.

Firstly, before printing, we need to do some preparation work.

1、 Pre processing procedure

01. Clean the powder from the forming cylinder

Open Tencent News and view more pictures>

Sweep the powder in the cylinder into the powder collection box with a brush.

02. Replace the scraper strip

In order to avoid the impact of scraper wear on the quality of printed parts, it is almost necessary to replace the scraper with a new one after printing.

03. Adjust the substrate

Before printing, it is necessary to adjust the screws at the four corners of the substrate to make it horizontal, otherwise it will also affect the quality of the printed part.

04. Sifting powder

The powder in the powder collection box needs to be sieved before it can be recycled. Sifting can remove impurities generated during printing and ensure printing quality.

05. Replace air

In order to prevent the oxidation of metal powder, nitrogen gas must be filled as a protective gas, and the replacement process takes about an hour and a half.

Due to the use of metal powder as the material for metal printing, many people may mistakenly believe that metal printing does not require support. This statement holds true for nylon SLS printing, but for metal printing, support is necessary and often necessary.

The main functions of metal 3D printing support are: (1) connecting with the printing platform, resisting stress, and preventing edge warping; (2) Resist the force of the scraper and maintain the shape of the parts; (3) Conducting heat.

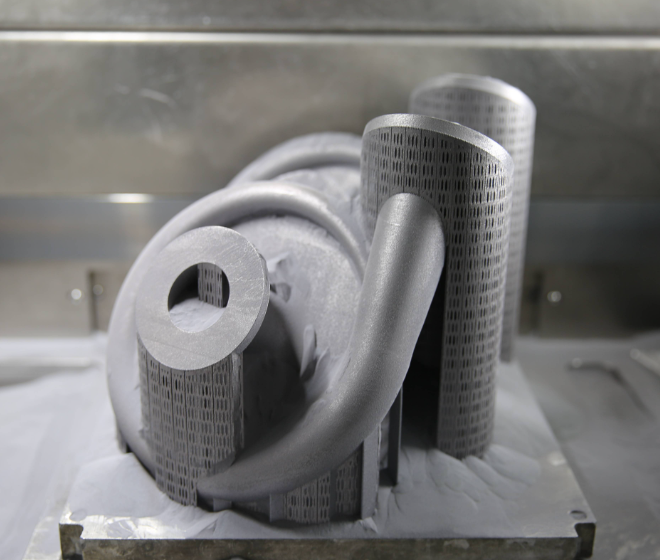

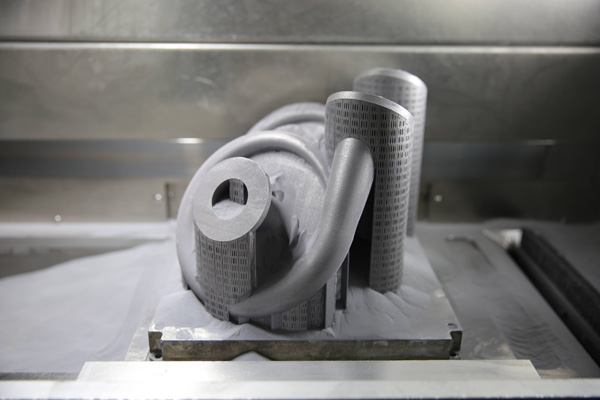

This is the state when the parts are supported. Since the support is also made of metal, it is difficult to remove, so operators will repeatedly adjust the angle to minimize the support.

After the preparation work is completed, import the supported print into the machine and start printing.

2、 Post processing procedure

After printing is completed, it needs to be left to stand for a period of time. After it has completely cooled down, the printed part and the substrate should be taken out together.

At this time, the printed part is sintered on the substrate.

heat treatment

Before cutting, it is necessary to perform heat treatment to relieve stress, especially for some large flat box shaped thin shells, which have strong stress and are easily deformed when cut directly.

Wire cutting

After heat treatment, perform wire cutting to separate the printed part from the substrate.

This is the state when it was just cut off, and it can be seen that there are still many supports on some parts.

Go support it

The main difference between metal printing and resin printing lies in the support. The support of resin parts is relatively easy to remove after being soaked in alcohol, while the support of metal parts is very hard, almost equivalent to welding on the printed part. Therefore, removing the support is also the biggest difficulty of metal printing.

This is just a part of the metal post-processing tools. To remove the support of a piece, it often requires various martial arts skills, and sometimes it takes several days for a post-processing master to remove the support of a piece!

This is the effect after removing the support, and the white fur adhered to it is fiber taken from the gloves of our post-processing master! Too southern!

polish

Polishing is to smooth out the support points and make the surface of the printed part smoother.

sand blast

After polishing, sandblasting is required, which can make the surface of the printed part cleaner and the effect more beautiful.

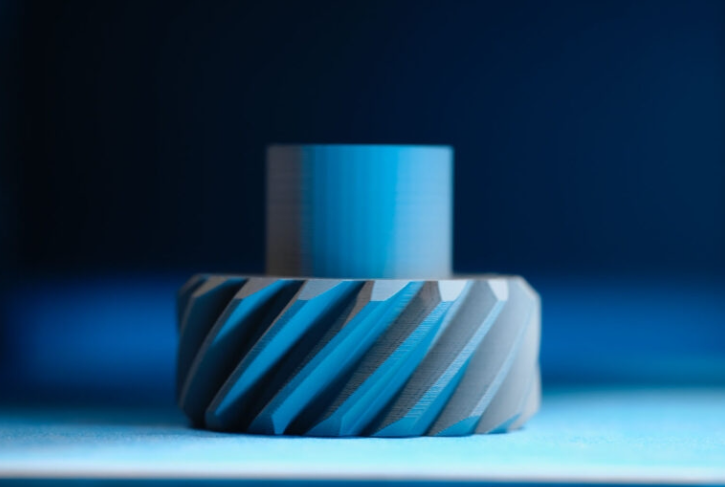

If there is no need for polishing or other treatments, this is the final result! Of course, polishing can also be performed as needed.

polishing

Polishing can reduce the surface roughness of the workpiece and obtain a bright and smooth surface.

The process of metal printing from early preparation to offline post-processing is various, and it is relatively difficult to support it. Therefore, the normal delivery time is about 7 days. Customers who are accustomed to delivering within 24 hours of resin printing may not accept it for a while, but after reading today's sharing, I believe you can understand more and worry less.

Add WeChat

Add WeChat