Laser Cleaning: Advantages and Applications of Laser Cleaning Systems

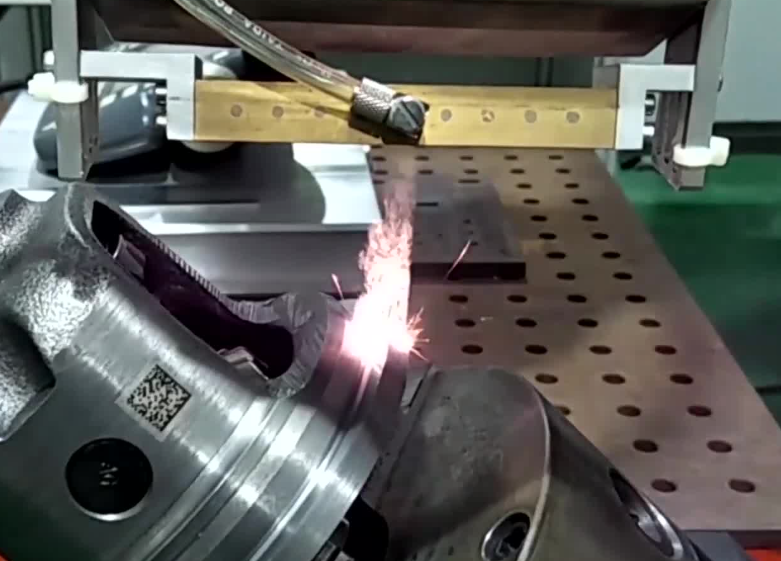

The laser cleaning system is a highly integrated system of cleaning lasers and industrial robots. Mainly composed of laser and laser cleaning head, control system, chiller, and accessories. It can achieve precise cleaning and simple operation in the process of automated cleaning.

Cleaning advantages:

1. The process of using a high-energy laser beam to irradiate the surface of the workpiece, causing instantaneous evaporation or peeling of dirt, rust spots, or coatings on the surface, thereby achieving a clean and purified process

2. Industrial mold cleaning, rust removal, paint removal, etc

3. Quick and efficient cleaning, no damage to the substrate, and good accessibility

Industry applications:

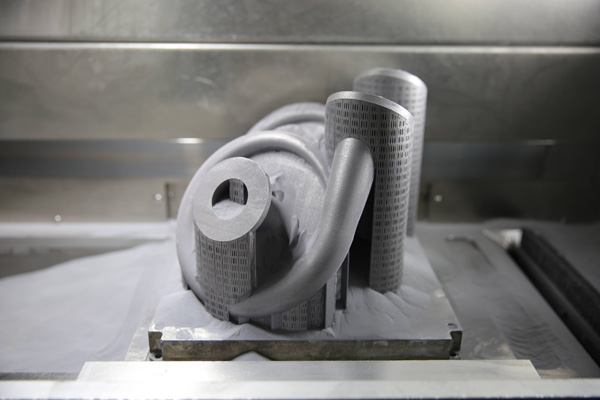

Application industries: high-speed rail, aerospace, marine, automotive, mold, rail, nuclear power, machinery, sheet metal, electricity, cultural relics, etc.

Processing objects: molds, gears, guide rails, pistons, aluminum alloys, titanium alloys, hot-rolled steel, etc.

Laser cleaning technology is an important link in industrial production and other fields. It overturns traditional cleaning techniques such as chemical cleaning, mechanical polishing, dry ice cleaning, and ultrasonic cleaning, and is a rapidly developing new cleaning technology in recent years. Laser cleaning has many unique advantages: it can improve cleanliness; Short cleaning cycle; Low operating costs and automated operations; Quickly and effectively reach the designated location; It can perform corner cleaning and gradually replace traditional cleaning processes in the field with its unique advantages.

The article is reposted online. If there is any infringement, please contact me and the content will be deleted as soon as possible. Thank you.

Add WeChat

Add WeChat