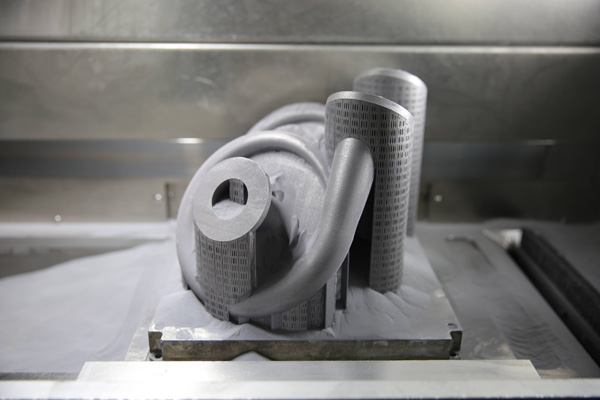

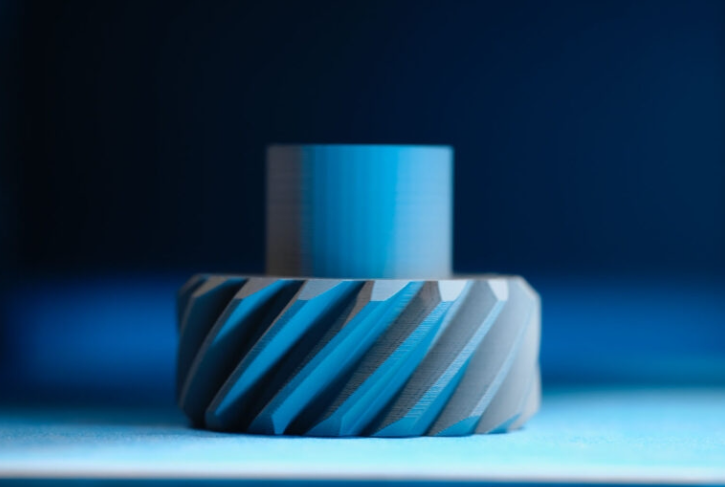

Summary of Powder Forming Process Methods for Metal 3D Printing Technology

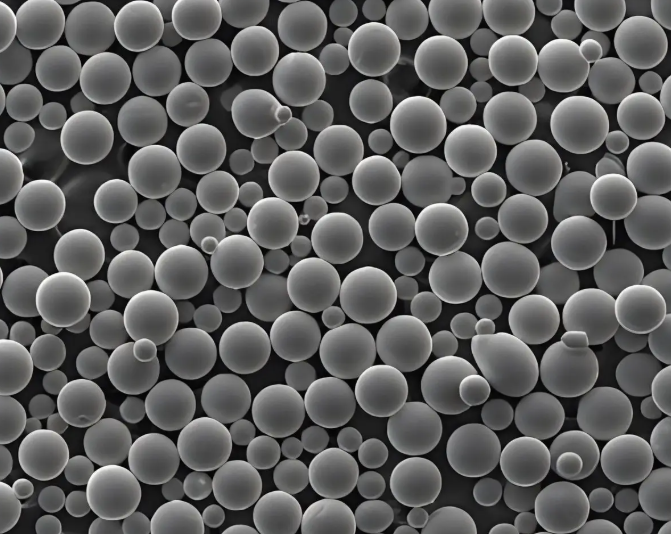

3D printing metal powder is the most important link in the metal parts 3D printing industry chain and also the greatest value. At the 2013 World 3D Printing Technology Industry Conference, authoritative experts in the global 3D printing industry provided a clear definition of 3D printing metal powder, which refers to a group of metal particles with a size less than 1mm. Including single metal powders, alloy powders, and certain refractory compound powders with metallic properties. At present, 3D printed metal powder materials include cobalt chromium alloys, stainless steel, industrial steel, bronze alloys, titanium alloys, and nickel aluminum alloys. However, in addition to good plasticity, 3D printed metal powders must also meet the requirements of small particle size, narrow particle size distribution, high sphericity, good flowability, and high loose packing density.

Due to different application and subsequent forming process requirements, the preparation methods of metal powders also vary, mainly including physical and chemical methods and mechanical methods according to the preparation process. In the powder metallurgy industry, preparation methods such as electrolysis, reduction, and atomization are widely used. However, it should be noted that both electrolysis and reduction methods have certain limitations and are not suitable for alloy powder preparation. Currently, metal powders used in additive manufacturing are mainly concentrated in materials such as titanium alloys, high-temperature alloys, cobalt chromium alloys, high-strength steels, and mold steels. To meet the requirements of additive manufacturing equipment and processes, metal powders must have characteristics such as low oxygen and nitrogen content, good sphericity, narrow particle size distribution range, and high bulk density. The plasma rotating electrode method (PREP), plasma atomization method (PA), gas atomization method (GA), and plasma spheroidization method (PS) are currently the main preparation methods for metal powders used in additive manufacturing, all of which can produce spherical or nearly spherical metal powders.

Preparation method of metal powder

1. Plasma Rotating Electrode Method (PREP)

Plasma Rotating Electrode Communicating Process (PREP) is a spherical powder preparation process developed in Russia. The principle is shown in the figure, which processes metal or alloy into a rod and heats the rod end with plasma. At the same time, the rod rotates at high speed, relying on centrifugal force to refine the molten droplets. It solidifies in an inert gas environment and spheroidizes into powder under surface tension; By sieving powders of different particle sizes and subjecting them to electrostatic removal (only applicable to high-temperature alloys), the final powder product is obtained.

The PREP method is suitable for the preparation of alloy powders such as titanium alloys and high-temperature alloys. The metal powder prepared by this method has high sphericity and good flowability, but the powder particle size is coarse. The SLM process has a low yield of fine particle size (0-45 μ m) powder and high cost of fine powder. Due to the fact that the thickness of the powder, i.e. the size of the droplets, mainly relies on increasing the rotational speed or diameter of the rod material, increasing the rotational speed will inevitably require higher requirements for equipment sealing, vibration, etc.

At present, the most advanced equipment and core technology of PREP are still in the hands of Russia. Domestic units mainly rely on direct introduction or absorption digestion improvement after introduction to master some technologies. The China Iron and Steel Research Institute, Beijing Aerospace Materials Research Institute, and Northwest Nonferrous Metals Research Institute introduced PREP equipment from Russia in the early stages, but there is a significant gap between the current equipment process technology level and the international advanced level. Domestic universities such as Xi'an Jiaotong University and Central South University have carried out basic research on PREP process technology. The Iron and Steel Research Institute and Zhengzhou Machinery Research Institute jointly developed the first large-scale PREP equipment in China for the development of alloy powder materials, but the yield of titanium alloy fine powder is still not ideal. In recent years, Xi'an Ouzhong Company has imported two sets of PREP equipment from Russia, and AVIC Maite and Hunan Dingli have also independently developed complete sets of PREP equipment. The yield of titanium alloy fine powder (≤ 45 μ m) is less than 20%. Overall, there is still a gap in overall performance between China's early imported and currently independently developed PREP equipment and Russia's. Advantages: clean surface, high sphericity, few accompanying particles, no hollow/satellite powder, good flowability, high purity, low oxygen content, narrow particle size distribution. Disadvantages: The powder particle size is relatively coarse, the yield of fine-grained powder is low, and the cost of fine powder is relatively high.

2. Plasma atomization method (PA)

Plasma Atomization (PA) is a unique metal powder preparation technology developed by AP&C Corporation in Canada. A plasma torch symmetrically installed at the top of the melting chamber is used to form a high-temperature plasma focus, which can even reach up to 10000 K. A dedicated feeding device sends the metal wire into the plasma focus, and the raw material is rapidly melted or vaporized, dispersed and atomized into ultrafine droplets or mist by the high-speed impact of the plasma. During the flight deposition process in the atomization tower, it is cooled and solidified into ultrafine powder through heat exchange with the cooling argon gas introduced into the atomization tower. The schematic diagram of the PA equipment is shown in the figure.

The metal powder produced by PA method has a nearly regular spherical shape, and the overall particle size of the powder is relatively fine. AP&C has partnered with Arcam, a Swedish company, to expand and enhance production capacity in response to the rapid development of the additive manufacturing market. Due to the high temperature of the plasma torch, theoretically all existing high melting point metal alloy powders can be prepared by PA method. However, the use of wire atomization powder in this technology limits the preparation of many difficult to deform alloy material powders, such as titanium aluminum intermetallic compounds. At the same time, the pre preparation of raw material wire increases the cost of powder preparation. To ensure quality control of powder particle size and other aspects, production efficiency needs to be improved.

Advantages: The yield of powders below 45 μ m is extremely high, with almost no hollow sphere gas entrainment, which is superior to the atomization method. The TC4 alloy used in Arcam electron beam forming was prepared using this method. Disadvantages: Poor sphericity, satellite powder, and high cost of silk material.

3. Aerosolization method (GA)

At present, commonly used techniques for the preparation of metal powder materials for additive manufacturing include Vacuum Induction Melting Gas Atomization (VIGA) and Electrode Induction Melting Inert Gas Atomization (EIGA). The VIGA method uses a crucible to melt alloy materials, and the alloy liquid flows through the bottom conduit of the intermediate package to the atomization nozzle, where it is crushed by supersonic gas impact and atomized into tiny droplets at the micrometer scale. The droplets spheroidize and solidify into powder. This method is mainly suitable for the production and preparation of powders such as iron-based alloys, nickel based alloys, cobalt based alloys, aluminum based alloys, copper based alloys, etc.

The EIGA method combines atomization technology with electrode induction melting technology, abandoning components such as crucibles that come into contact with the metal melt. The slowly rotating pre alloyed rod metal electrode is lowered into a circular induction coil for electrode melting, and the electrode droplets fall into a gas atomization nozzle system. Inert gas is used for atomization, which can effectively reduce the introduction of impurities during the melting process and achieve safe and clean melting of active metals. It is mainly used for the preparation of powder materials such as active metals and their alloys, intermetallic compounds, and refractory metals, such as titanium and titanium alloys, and titanium aluminum intermetallic compounds.

In recent years, powder manufacturers and powder equipment manufacturers have developed technologies such as ultrasonic gas atomization, tightly coupled gas atomization, laminar flow gas atomization, and hot gas atomization through improvements in atomization powder technology. They have also made improvements to related technologies based on the characteristics of additive manufacturing technology, and can now prepare powders that meet the requirements of additive manufacturing processes such as laser selective melting SLM and laser coaxial powder feeding. Advantages: High yield of fine powder, below 45 μ m can be used for laser selective melting, and the cost is relatively low. Disadvantages: Poor sphericity, high satellite powder content, high hollow powder content of 45-406 μ m powder, air entrainment, unsuitable for powder metallurgy fields such as electron beam selective melting and direct hot isostatic pressing.

4. Plasma spheroidization method (PS)

Radio frequency plasma has the characteristics of high energy density, high heating intensity, and large volume of plasma arc. Without electrodes, it will not contaminate the product due to electrode evaporation. The principle of RF plasma powder spheroidization technology is that under the action of high-frequency power supply, inert gas (such as argon) is ionized to form a stable high-temperature inert gas plasma; Irregular shaped raw material powder is sprayed into the plasma torch through a powder feeder using a carrier gas (nitrogen). The powder particles absorb a large amount of heat in the high-temperature plasma and quickly melt on the surface; And it enters the reactor at a very high speed, rapidly cools under an inert atmosphere, solidifies into spherical powder under the action of surface tension, and then enters the collection chamber for collection.

Advantages: The powder has a regular shape, high spheroidization rate, smooth surface, and good flowability. High melting temperature refractory metals such as tantalum, tungsten, niobium, and molybdenum can be prepared. Disadvantages: Long heating cycle, easy generation of volatile elements, large surface area of irregular powder, high oxygen content.

5. Method comparison

The particle size distribution of the powder prepared by PREP method is narrow, making it difficult to obtain fine powder and resulting in a low yield of fine powder. Due to the high cost of fine powder, its application in SLM process is greatly limited. The coarse powder prepared by this technology has been applied in the laser rapid prototyping LSF process. The PA method has been used for batch preparation of conventional grades of titanium and titanium alloy powders, which contain satellite powder, flake powder, nanoparticles, etc. After treatment, the powder has good flowability. Due to the need for silk as raw material, this technology has encountered bottlenecks in the preparation of difficult to deform metal materials, resulting in a narrow range of material applicability. The production cost of non active metal powders such as nickel based alloys and iron-based alloys is relatively high. Due to its high efficiency, wide alloy adaptability, low cost, and controllable powder particle size, VIGA powder method is a widely used technical method by additive manufacturing powder suppliers worldwide. Compared with the PREP method, the EIGA method has the advantages of saving materials, flexible production, and producing more fine powders in the preparation of active metal powders. It is suitable for the production and preparation of titanium alloy powders for SLM process. The PS method uses high-energy plasma to produce highly spherical and dense metal powders. Its raw material is non spherical powder with high oxygen and hydrogen content, making it difficult to control the oxygen content of its spherical powder. The yield of fine powder also depends on the particle size of its original powder. The additive manufactured metal powder that has been repeatedly used can be used as a raw material for the PS method for re powder production.

Comparison of several methods for preparing metal powders

The global additive manufacturing technology industry is in a period of rapid development, and in terms of additive manufacturing materials, equipment, processes, applications, etc., Europe and America are developing more comprehensively and systematically. The development of additive manufacturing technology in China is mainly focused on the printing and forming process, with insufficient attention paid to the research of alloy materials. There is a significant lack of investment in the research of manufacturing equipment and process technology for powder materials, and the development of new alloy powder materials and low-cost multi process composite powder technology has not been widely carried out. The lack of basic equipment construction and process technology research has greatly affected the construction and development of China's independent additive manufacturing material technology system.

Add WeChat

Add WeChat